The Roundhouse Journal December 2002

EditorialThe track day season has been pretty good most of the season, the last public open day at the end of October was an absolute sell out with crowds coming out of the woodwork from all directions, everything we had that was serviceable, was pressed into use. All the public seemed to thoroughly enjoy them selves, even if this left us all knackered at the end of the day. Thank you to everybody who lent a hand, it was appreciated.

The 7¼" open day in October was weather wise really wet all of the time, we had a lot of visitors on the Ground Level track, which was topped and tailed with Stella's marvellous buffet lunch / afternoon tea & cakes. From what I could see our visitors seem to enjoy themselves enormously.

Talking of track laying, the 71/4" track over the Alps line is now complete from Angel Road signalbox to Hampton Court Junction. The retaining wall fencing on the downward slope is now being tackled.

From October through March this winter the local past Angel Road is being relaid. The retaining wall that separates the ground level track from the raised track (about 5' higher at that point) was placed very close to the ground level track - too close as one person's knee can testify. It has been decided to slew the ground level track away from the wall and to increase the clearances to the minimum standard for new work. The first part is targeted to be finished before Santa (weather permitting) and the second half before Easter - total of about 250'. This will then complete the resleepering and relaying of every piece of track on main, local and sidings from the Level Crossing past Willowbank to Angel Road.

At present we are just about keeping pace with the deterioration of the sleepers due to age and rot - the track generally has a lifetime of about 15 years between resleepering. Usually the track can simply be resleepered, (cutting out ends that have dipped). Sometimes kinks have to be pressed out if the track has distorted, but if there are severe problems the track is scrapped - with chairs welded to it, one cannot pass it through the bending rolls again.

However the situation is not so good for the remaining track backwards towards Hampton Court Junction and through to the Maintenance Shed. Much of this will be scrapped where it has been corroded beyond salvage by the signalling track circuits - we have already had to patch out some bad pieces already. Hopefully we will get through that area quickly enough to be ready to start the next revolution of the track when the next cycle of renewal is necessary.

Planned for the Summer and Autumn next year is the renewal of the track from Angel Road facing point back towards the tunnel (now called the Local since the Alps is to be the Main). Relaying will match completion of Work on the Alps. The stretch at the Angel Road end is dependent on the concrete capping work being completed on the wall between the Local and the Main. The relaying job is about 200 ft, long with 42 ft inside the tunnel. Tunnel Junction facing and trailing points just before the tunnel entrance will be re-engineered / resleepered & a new trailing point will be installed at the tunnel exit in readiness for the next track that loops by the raised track to link with the point already installed in (yes IN) Willowbank Arrivals Platform.

Willowbank Signalbox has had its new industrial signal interlocking computer installed & commissioned earlier this year. It has worked well with only a couple of minor software updates necessary to overcome operational problems earlier in the season

Angel Road Signalbox has inherited the old industrial signal interlocking computer from Willowbank signalbox, this will be fully operational early in the new year. Without boring everybody with tons of technical information, the installation has involved a great deal of rewiring and the installation of a new set of power relays so that the new Alps line can be used, which was the reason for the change / rework in the signalbox in the first place..

Jonathan Wright one of our Juniors must be commended and thanked sincerely for volunteering to paint two of the very large signalling gantries on the ground level railway track. Both these gantries look great now in overall white, with back 'boots' at ground level. Thanks for a job well done.

Report on Committee Meeting 7th November 2002.

A vacant and engaged bolt Is to be fitted to the outer door of the ladies toilet for the benefit of any disabled people to maintain there privacy.

We have five new members this month, John Clouder, William Kerwin. Chris Randall, Simon Peck, and Adrian Kidwell. A warm welcome to them all.

The annual rummage sale will be on Friday the 29th of November The list is on the notice board for anyone who would like to enter Items for this sale Please put your name against a number mark all items clearly with this number i.e. Stick it on not just lay it on and hope It wont get lost, likewise if you wish to place a reserve price on an Item make it clearly visible if you do not it will be sold to the highest bidder at whatever price it reaches. All unsold items must be removed by the seller after the end of the auction. Also if you purchase any lot and It has anything you do not want in it take it home with you do not put it in the dustbin or leave it In the clubhouse.

Plans for the base of the raised track traverser base were approved last night so it will soon be started help will be required for this project if you are willing please contact Steve Grey the raised track co-ordinator who will be more than glad of your assistance.

Santa special time is coming around again on Sunday 8th December and there is a need for more help at this time from all members may I remind you of what it says on the application form you all signed on joining this club that you will assist the society. This Is not personal to any member in particular but it would be nice if some of those members who never come to a track day to assist would give some time to help This event makes a tidy sum to the clubs funds from which you all benefit There is nothing strenuous for you to do just assist with guard duty, crossing keeping crowd control, etc this would enable the hard core of the members who usually run this event to take It a bit easy. And if enough of you help it will only take you a couple of hours of your time.

We have a large welding machine in the workshop that so far has never been used It can do tig mig and stick welding etc, the problem is that due to the large amount of equipment that we have space is at a premium some members of the workshop group would like to get rid of it and some would like to keep it, In its day it was the state of the art machine by today's standards it is fairly obsolete we have several stick welders around the site the reason for telling you all this is to canvas your opinion as to weather It is kept or disposed of.

Now for something you can all enjoy the BBC Is doing a live broadcast from Kempton pumping station at 6pm on December the 4 th tickets are free you just need to put your name on the list on the board. There is an age limit of 9 years and over free refreshments will be served in a marquee before the show. Oh yes 1 forgot to tell you the name of the show Best inventions.

The AGM will now take place in January, as I believe I told you William is standing down as Hon Secretary at that time so we will be looking for someone to take his place think about It is a very important job perhaps you could do it if so please volunteer your services.

The loco that I look after 'Tom Snoxall' is well on the way to being finished as soon as the fittings are located in the cab it will go for painting.

Our next committee meeting will be on DEC the 5th

Peter Pullen for MDSME Committee.

Book review - Railway Track Diagrams - 5 England South and London Underground -

Published by Quail Map Company £8.95 (01392 430277)

For those who have an interest in railway track diagrams, or those who simply want some ideas for a smaller model railway, this new publication will be of interest. In 55 pages, there is a comprehensive record of most railways in Southern England - and this means all the track - not for example just every platform and point at Victoria Station but all the track to the Channel Tunnel terminal in France along with platform numbers and carriage lengths, mileage, bridges, tunnels and sidings. Bounded by Exeter to the West, London to the north and Coquelles to the East, every significant piece of railway track seems to have been captured. This includes the Croydon Tramway, the Post Office Railway, private railways such as Kent and East Sussex and Volks Electric, narrow gauge railways such as Sittingbourne and Kemsley, and a large number (but not all) of the miniature railways, such as Moors Valley and the MDSME.

The book is published in A4 soft cover format, but uses high quality paper. While the detail is small, good quality printing makes the diagrams clear to read. It is quite surprising just how much detail has been put into this publication. From the sight of most diagrams, they appear to be reasonably up to date, with most trackwork valid within the last two years. The publishers need congratulations on the effort that must have been expended to put this compendium together.

A copy of the book is in the club Library

Martin Baker

THE ORIGIN OF THE SPECIES

Or the evolution of the large British Railways standard locomotive by logical selection

This article is intended as food for thought and represents British locomotive development as I see it. Perhaps those more learned than I will wish to disagree; as I have said, this is how I see it. Some of the connections may be regarded as rather thin, but this is not without precedent: For example, Henry Tudor's claim to the throne was somewhat tenuous but it didn't stop him taking it. What's more, with a superb propaganda coup he and his successors managed a complete character assassination of his predecessor poor old Richard III

So, back to the subject. When Dugald Drummond moved south from the Caledonian Railway, he brought with him a legacy of express locomotive development based mainly upon the 4.4.0. wheel arrangements. There being one notable exception, the single wheeler No 123 but that was purely an experiment. Of his 4.4.0. types there was continual improvement from his earliest locomotives on the North British, then on the Caledonian such as the Dunalastairs and finally on the L&SWR , where he produced his most successful design the T9 fondly remembered as the Greyhounds. The T9 went on to be developed into ever more powerful types culminating in the DI5 class. Drummond however had started to experiment with the 4.6.0. arrangement, but alas, the performance of these engines left a lot to be desired. To be fair to him he was breaking new ground and his final 4.6.0. class looked absolutely magnificent with huge long splashers; complete with portholes. The T14 or paddlebox as they became known were by far the largest engines in the south of England.

Upon the death of Drummond and the appointment of R.W. Urie as C M E the big Drummond classes were examined and their more fanciful ideas discarded. In Urie's new design., gone was the four cylinder layout, the deep Victorian splashers and the cross water tubes in the boiler. But retained were the main dimensions, the 4.6.0. wheel arrangement and the huge bogey tender. Urie's first 4.6.0. Was the HI5, a very advanced design which went on to be developed into the King Arthur class and the mixed traffic S 15 class.

With the creation of the Southern Railway and the appointment of R.E.L. Maunsell as CME both King Arthur and S 15 classes were given more modem fittings including side window cabs and as such continued in production for some years. However the need was becoming apparent for a more powerful locomotive capable of hauling the heaviest expresses of the day, in the Southern's case, the boat trains. So was born the Lord Nelson class, which bore a distinct family likeness to the King Arthur's but with a reversion to four cylinders and a new Belpaire boiler, an interesting feature of the design was cranks set at 135 degrees giving eight puffs per revolution. Unfortunately their performance in the early years was disappointing, but upon subsequent modification to the front end by O.V. Bulleid they did sterling work. But from the start they looked the part and with their patriotic names of past British Admirals they caught the public attention, And they were very powerful engines indeed.

At about the time Lord Nelson first appeared Sir Henry Fowler of the newly formed L M S was under great pressure from the operating department to quickly produce greater motive power for the express trains. Whilst the midland section could just about manage with their compounds, the western section was struggling with the hilly main line to Scotland. The most powerful engine they possessed being the Claughton class 4.6.0. The Claughton's themselves were born of a natural evolution within the L&NWR from the early 4.4.0.'s such as Jubilee's, through King George Vs, to the early 4.6.0.'s such as the Experiment class and the later Prince of Wales class. The Claugton's, equipped with front wheel drive and a filigreed valence they must have looked magnificent in their original lined out blackberry black. It must forever remain a tragedy that upon withdrawal of the last of the class in 1949 she went straight to the cutters torch: For in my hopelessly biassed opinion she represented one of the most pleasing designs to appear north of Southern metals.

It was in a somewhat devious manner, largely behind Sir Henry's back that arrangements were made to test a G W R locomotive over the L&NMR main line. Such was the success of this engine, Launceston Castle, that the L M S asked Swindon to produce fifty Castles as quickly as possible. This was flatly turned down as was a request for the loan of detail drawings. Such was the desperation in the C M E s office in late 1926, they being faced with the prospect of almost every express of the 1927 summer season being double headed: That a request was made to the Southern for help, where the reception was wanner. After a brief meeting at Waterloo, a complete set of Lord Nelson drawings was dispatched to the North British Locomotive Co. in Glasgow, where they were used as the basis for one of the most famous classes of all time. Modified to three cylinder format, with water pick up gear and other L M S features the new Royal Scot class was hastily put into quantity production. Whilst these locomotives performed well and did some splendid work, they, like the Nelsons suffered steaming difficulties. This was overcome by the timely arrival of William Stanier from the G W R, who promptly designed a Castle type taper boiler complete with Swindon top feed and Belpaire firebox; which when fitted to the Royal Scot produced a power unit that was second to none.

Before the arrival of Stanier the Royal Scot had been produced in a lighter version, although retaining generally similar dimensions and machinery they were equipped with a smaller boiler. The necessary authority for the construction of these Baby Scots being gained by stating them to be rebuilds of existing Claughton class loco's. In fact the first two did incorporate some major components from the Claughton's, the most noticeable items being the driving wheels complete with huge circular bosses. Many of the Baby Scots, or Patriots as they had become known were later modified by Stanier to carry a large taper boiler and thus became almost indistinguishable from their larger sisters.

Under the direction of Stanier the Patriot design was reworked and brought up to date entering production as the L M S Jubilee class and thus went on to become the most numerous express class to be produced in Great Britain. She was a beautiful engine and several have been saved for posterity. The Jubilee theme was expanded to include a two cylinder mixed traffic version with larger boiler, which was undoubtedly the most successful British locomotive of all time: The Stanier black five, she went on with little alteration to become the B R standard class five. The black five was also produced in an eight coupled version becoming the Stanier 8 F of which more than eight hundred were built. This engine in turn was developed by R A Riddles for the ministry of supply into the W D 2.8.0. and W D 2.10.0. classes all three of which formed the backbone of allied rail transportation at home and overseas.

Stepping back in time to the turn of the last century and the situation on the G W R with the company still suffering from the expensive changeover to standard gauge track. In 1902 at the time G J Churchward took over from William Deene as locomotive, carriage and wagon superintendent the usual situation was manifesting itself. Namely a locomotive stock not up to the 'oh of handling the ever heavier trains. This absolute genius of a man set straight to work and produced his first 4.6.0. that same year, given the number 100 this design was developed with taper boiler and other refinements to produce in 1903 the forerunner of all subsequent G W R 4.6.0.'s. Carrying the number 98 she had a two-cylinder layout with inside valve gear, the evolutionary process taking her through the Saint, Hall, Manor, Grange and County variations. She also formed the basis of the design for North Star, a four-cylinder loco with two sets of valve gear positioned between the frames, the outside piston valves being driven by rocking levers. She was originally built as an Atlantic to allow for comparison trials against similar Star class engines built as 4.6.0.'s. This design evolved under the direction of C B Collett as did the two cylinder engines but in this case to become first the Castles then the majestic Kings, the most powerful 4.6.0.'s of all time.

Back to the year 1933 and the L M S with the newly appointed William Stanier fresh from Swindon as C M E intending to make his mark by meeting the operating department need for a "big engine", and a big engine they would have. She duly arrived and was named The Princess Royal, a huge Pacific based very much on the working parts of the G W R King but with the valve gear repositioned to the outside with the inside cylinders being driven by rocking lever, later engines had four sets of valve gear. She had a boiler of enormous length with a wide firebox which gave rise to steaming difficulties; later to be equipped with a combustion chamber to shorten the tubes which cured the problem. Of the twelve built the third, number 6202 was produced as a non condensing steam turbine locomotive which was universally known as the Turbomotive and did many thousands of miles in this form. Due to the high cost of renewing the turbine she was rebuilt as a conventional Pacific in 1952, Christened Princess Anne she sadly suffered complete destruction only a few months later in the terrible accident at Harrow,

Following the success of the Silver Jubilee streamliner on the LNER; the LMS were determined to have a prestige train of their own. As it happened there would soon be a Coronation, so what better excuse could there be for a fast luxury train. So it was that William Stanier produced his masterpiece, the fully streamlined Coronation Scot. Headed by a massive Pacific which was in effect an enlarged Princess Royal with 6ft 9in driving wheels and greater cylinder capacity, so as to maintain the same tactile effort but at a higher speed.

Back in the closing years of the nineteenth century but this time on the Great Northern whose principle express engines "the Stirling Singles" were becoming increasingly light footed under the increasing weight of traffic. H A Ivatt the locomotive superintendent designed a well-proportioned Atlantic with a narrow firebox, a handsome engine with power to spare but lacking in steam production. So followed the large Atlantic with a round topped wide firebox sitting on top of the frames, the first of its type in Britain: To us of course its LBSC's Masie. This class of locomotive performed well and gave all that was asked of it, and was to carry on for many years alongside the Pacific's designed to replace it. So successful in fact that larger cylindered versions were produced by Earle Marsh at Brighton for the LB&SCR; designated the HI and H2 class they were later named after headlands in southern England. One of their number being successfully used by Bulleid to test the feasibility of sleeve valves for use in Leader.

With the retirement of H A Ivatt and the appointment of H N Gresley as C M E the Atlantic's were examined and in 1923 out came a Pacific with enormous round topped wide firebox boiler. She was equipped with an eight-wheel tender and extremely free running three cylinder machinery, the centre one using valve motion derived from the outside Walschaert's gear. She looked and indeed was a true thoroughbred, she was of course the first of the beautiful A l's of which Flying Scotsman is still thankfully with us. Later fitted with a lower cab and boiler fittings to increase route availability over the new LNER and with higher boiler pressure they became the A3's, soon to be developed and refined into Sir Niggles record breaking A4's. An offshoot of the A3 was another of the most pleasing designs in locomotive history, the P2 2.8.2's designed for the heavily graded routes north of Edinburgh.

Then came disaster; Edward Thompson, a C M E determined it would seem to undo all the good work of Sir Nigel Gresley and replace the Racehorse with the Camel. For some inexplicable reason (lets hope it was coincidence), Sir Nigel's very first Pacific, which had been hastily named Great Northern before the grouping was chosen for butchery. She was mercilessly disfigured, gone were the graceful lines, the outside cylinders were moved back leaving the front bogey starkly contrasting with a mass of bare frame plate above. The conjugated valve gear was gone and replaced with an extra set of Walschaert's, it has been suggested that the cylinders were moved to allow for the same length of connecting rods on the divided drive which Gresley had given her. As a final gesture she was bedecked with quite the ugliest smoke deflectors ever to appear on a British Locomotive. She did however form the basis of the design for the later Peppercorn AI whereupon the cylinders were returned to their rightful place.

Among the other contentious things done at that time were the chopping short of the beautiful P2's, they were elegant machines but had not fared well under wartime maintenance conditions. They did not deserve however to have their frames shortened and one pair of driving wheels removed to produce arguably the worst looking Pacific sub class ever to turn a wheel in this country. As if that were not enough some of Gresley's highly successful V2 class 2.6.2's were altered on the stocks to produce another sub class of make shift Pacific. Why build a Pacific to do the job of a Prairie? If or one cannot imagine. These sub classes came under the lead designation of A2.

There was to be one more great creation from Sir Nigel Gresley and that came in the form of his prodigy 0 V Bulleid, who on his appointment as C M E to the Southern Railway brought with him many of the best Gresley ideas. Among these were a superb free steaming boiler allied with a free running three cylinder layout. His first major design for the Southern was of course the Merchant Navy class air smoothed Pacific, complete with miniature Walschaerts valve gear chain driven and running in an oil bath. After initial troubles they along with their smaller sisters the West Country and Battle of Britain classes did sterling work and were the mainstay of steam in the south and south west until the end of steam in London in July 1967.

Now the final phase, when the British Transport Commission met to discuss the motive power requirements of the newly formed British Railways. R A Riddles from the L M S as member for mechanical and electrical engineering was given the task of overseeing the design of the new standard classes, which would eventually be twelve in number. After running exchange trials for the purpose of comparing the performance of locomotives of different regions in like for like conditions; Mr Riddles and his team did a splendid job of taking the best features of the latest designs of the constituent companies and building them into new engines. The first of these being the class 7P Britannia, rolled out in early 1951. Bearing a striking similarity to the later un streamlined L M S Coronation or Duchess class, she owed a lot to the Merchant Navy class particularly in the free steaming boiler. As a lad I well remember the awe inspiring sight of 70004 William Shakespeare at the south bank exhibition pristine and finished to exhibition standard. From the Britannia came a small boiler version, the 6P Clan class for use in the Scottish region; no doubt inspired by the success of West Country pacific Yeovil in the Highlands during the aforementioned 1948 exchange trials.

The tragedy at Harrow in 1952 in which the ex Turbomotive was destroyed left a gap in the west coast locomotive inventory. The opportunity was taken to build the ultimate British express locomotive, a class 8P with the latest Caprotti valve gear and utilising the Gresley Bulleid three cylinder arrangement. She or should I say he was named Duke of Gloucester and resembled a Britannia of Duchess proportions. A magnificent engine which as an only child never had the opportunity to prove itself in service, however in preservation with modified draft arrangements she has proved to be everything her makers intended.

Then came the last and possibly the best of all the standard classes, the 9F: In all probability the most efficient steam locomotive ever to run in Great Britain, if not the World. A really cosmopolitan design developed from the Britannia and the WD2.10.0, both of which could trace their ancestry back more than fifty years. A freight locomotive capable of express speed allied with minimal maintenance and excellent fuel consumption.

One can only dream as to what might have been had we been blessed with people of vision in high office. Every conceivable trick has been played to besmirch the steam locomotive, such was the relentless barrage of abuse targeted at our most faithful of servants that I almost started to believe it myself. But the smear didn't stick, lies seldom do, and the faceless vandals who so irreparably damaged our railways are held in universal distain: Whilst the steam locomotive running on lines that they tried to shut down is adored by young and old alike. You see there was not one among the faceless men of the calibre of William Shakespeare who so successfully completed the campaign against poor old Richard III..

What am I building? Evening Star of course. Alan Rowell

Running the Minx - Part 1

Sunday 12 Dec 2000

Santa Specials

Had to retire early with no capability to sustain steaming. Sadly, lost the lid of John's Box of Bits with its oval engraved plate as above.

Weather very wet, site flooded outside 5" shed where they were pumping from GL tunnel foundations, also flooded from curve by Angel Road starting well before bushes, right round to beyond the bridge. I have never run with it so wet before. Got off to a sluggish start in heavy rain, lifting later to be relatively nice but with short heavy showers. The site generally was a mudbath. It got cold for guards after 3.30pm when the sun had all but set.

Loco in steam at 11 a.m. for start. Ran till 2.40 p.m. (3hrs 40 mins, c.f. normal afternoon 3½ hrs).

The coal was damp and dusty and probably blocked the super heater flues early on. Although I was running with a full firebox and it seemed bright, the loco was sluggish after the bridge and, apart from the first couple of laps, failed to respond to the challenge of the gradient.

I felt the gauge glass was not always showing a correct water-level.

Tried injector. Rattled the ball OK, but seemed to actually LOWER the water level in the boiler. Consider remaking clack top to reduce lift once more.

Poorly lubricated valve face may have contributed to running difficulties (had not left it soaking in oil from last time) and there were signs of steam blowing straight up the chimney.

Left longing for radiant superheats, variable blower/blast pipe arrangements, and CI cylinders.

On blow down, noticed the loco brake gear front offside seems very loose – must check they won't drop off before next time.

Stella had done wonderful food, hot soup, and was available with system of raffle tickets. She also did hot food for helpers afterwards – cheese and bacon pastry turnovers, pasties, mince pie. The day was a success and we had 13 customer comment forms, with only two mildly critical of poor sign age. Some said good value for money, and some were from kids saying thank you for presents. Those that did venture to the RT (gave 150 rides @ 50p, mostly in afternoon) often had multiple rides and really enjoyed it. We had the feeling that at 50p the money was not an issue. There was often a long queue on the GL, and sometimes they were in the rain. One person on the RT opened an umbrella after leaving the station!

15/16 April 2001 -

Easter Weekend

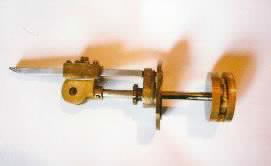

In preparation, made a new whistle valve with O-ring and PTFE washer from Trevor Collyer's design published in ME 29 Aug 1997 noting some dimensional errors in the drgs.

Replaced the pipe & fittings to the whistle with 3/32 bore / 5/32 OD pipe – seemed like going from the smallest to the largest – but did the trick on the long run to beneath the tender and the whistle now sounds loud and clear at a respectable pitch. As I wanted quite sharp bends in this pipe, I annealed those parts before bending it. It was then very soft to bend. I tried to leave the straight bits hard as supplied.

Completed restoration of the tender brake gear – never used – following Sam's mishap a while back. Whilst travelling at speed, the end of a trailing "safety" chain hooked round one of the J-bolts fixing the track, bringing loco, tender and young driver to a spectacular halt. The normally straight rod joining the rear tender brake hangers was bent like a letter "S" for Sam.

Made a new plug for the injector clack because the other had eroded threads, and ball seemed reluctant to seat after I'd removed 0.005" from it last year.

During the winter's track beam maintenance was lucky enough to notice an unusual "dead leaf" curled up between the two narrowest rails. On touching it, it turned out to be aluminium, discoloured on the underside with glue lines. Only on turning it over in my hand did I recognise it as the lid of "John's Box of Bits" with the engraved plate still attached, although curled into a semi-circle. I was thrilled to find it. Rupert straightened it one day and I made a new brass lid on Easter morning before Timmy arrived!

Took the Minx down on Easter Day. Ran rather well for half the afternoon till it started blowing steam up the chimney, and I enjoyed driving, blowing my whistle at the footbridge!

Back on the steaming bays I pumped some oil down the chimney, which usually fixes the blowing problem. Was just about to return to the track but thought I'd use the injector to fill the boiler first. The injector only succeeded in making the clack blow back. Tried rocking the loco and tapping the clack (which has never cured this fault, though it works a treat for the backhead clack) but then had to drop the fire. This leaky clack usually seats again if one can run round the track – but it doesn't feel comfortable. After blowing down and a cup of tea, I dismantled the clack and hosed it through, removing the lump of something that was in it. Also put the hose on the pipe from the injector to the clack. In the evening I removed the cones and soaked the injector in Fernox DS-3 de-scaler. It had huge precipitates of scale in both cones, and an obstruction so I couldn't see through. Probably an hour or so would have been enough. When I went to bed the injector was bright, but in the morning was covered with a black film of probably sulphide. The cones are now looser than ever before - they might fall out accidentally.

Easter Monday – took the loco and Timmy down fairly early. Julia, Agnes, Kerry and Ben's dad all came along – with lots of E.O. youngsters. A good time was being had. Also, Tom came down with Joshua. Emma Rose served ice-cream. Rupert was working with Brian sleepering track in-situ, or welding chairs etc. prior to running.

I steamed the Minx on arrival. Had to use the safety valve to fill the boiler as the backhead clack seemed blocked (though later in the day it was letting by and needs attention), and, after taking it round a couple of times, when the blowing seemed to be cured, I let Timmy take it. He drove for ages. Then Robert drove for a bit. Then Timmy grabbed one last lap before I took it back, lost all the pressure at the top by Angel Road and pushed it back to the station with the axle pump on! As Netta was about to join the track I took Minx back to the steaming bays to recover. I brushed out the flues and put it back on the track – but it was blowing up the chimney dreadfully when the regulator was opened. I took two loads of passengers. The first I barely got up the bank after the bridge – but then the superheaters took over and it was fine. The second was better, but generally weedy, and the loco was coming back into the station with no pressure. All this was due to the huge blowing spoiling performance. I took the loco off again to try the oil trick -– then put it back, but to no avail. There was still a huge blow – despite having had the boiler full to priming. So I gave up for the afternoon. The injector and clack were exemplary and I should clearly have pickled the injector at the first hint of trouble, or at least annually, and never messed about with the clack in the first place.

Chris C suggested PTFE piston packing. On speaking to John H, he was certain the blow would come, not from the valves, but from the superheater headers or steam pipe. Either way, the remedy pointed in the same direction – requiring dismantling to find and cure. John pointed out that removal of superheaters usually means removing the petticoat pipe to get clearance, and that when he took his out of the 9F they were so well wedged in he had to use a 7-ton tarpaulin strap and ratchet to withdraw it. When I suggested maybe it was time to do the boiler, too, he agreed maybe it was trying to tell me something…

The boiler contains some muck that I would love to be able to wash out. Some appeared in the gauge glass today. (Some time recently I removed the upper fitting plug and found the passage full of long pieces of scale that seemed to have floated in the water and washed into the passage – not just one. No wonder the water gauge had seemed sluggish!) The weather was rather cold, changeable, and threatening to rain most of the time. I wore my orange Hely-Hansen both days, but needn't have. In the brief sunny moments, the blackthorn above the RT at Angel Road was a picture.

Dismantling

Decided I can't keep going around saying I can't run because of blowing problems and then not doing anything about it (just because they've been intermittent).

On getting the loco home I began to dismantle. The blower pipe unscrewed, and the ring unscrewed from the chimney. If I'd known it was that easy to remove, I would have made another before now! On removing the snifter from the smokebox the pipe fractured even if it wasn't broken before. By gripping the steam pipe in gas pliers to hold it still and with a spanner on the nut, I got the superheater union undone. On reflection, the chimney is probably inserted permanently with the pin visible down the top locking the inner petticoat to the cap and outer profile. I therefore decided to withdraw the boiler, leaving the smokebox in situ. I removed the first boiler band, and piece of brass shim underneath. I removed the cab roof and two sides, retaining the 1/8" packing from under one side. I removed all the pipes from the backhead, together with turret and pressure gauge. It then became clear that the boiler is firmly cleated to a sliding stretcher plate under the rear of the foundation ring, and this plate rests on the frames, and is prevented from rising by a further cleat on each side. Removing the 5BA bolt from each side cleat frees both boiler and stretcher. I lifted the boiler out from the smokebox. On inspection there was a huge amount of soot and char obstructing/blocking the superheater flues, and completely hidden and inaccessible behind the two parallel header tubes. This clearly has to be removed more often and unblocked as part of regular maintenance. The superheater was attached to the boiler with cap-head socket screws, but the hole for the allen key was completely blocked and I undid them with pliers. They came out quite easily. I noticed the holes in the superheater flange had been elongated with a file to match with the boiler.

I shall try removing the superheaters by pulling with the Weston block, whilst having a pole from the beam to boiler to prevent lifting it from the ground. I shall wrap a continuous cord round the header between each element, and put that on the hook of the Weston block, which I hope will equalise the pull across the header. I shan't mind if it breaks, as I anyway intend ordering some more elements from Paul Gammon.

Now the boiler is off, I can easily remove the smokebox, and run the loco on air. This should reveal any blow from that quarter. I can also inspect the valves.

Thursday, 19 April 2001

Withdrawing the superheaters was moderately successful, and the cord was enough to spread the pull. Unfortunately the Steam Pipe from the regulator differs from LBSC's drawings, and instead of there being a plain flange with the superheaters bolted on (and which would have separated easily) the Steam Pipe protruded ½" as a close fit into the boss on the header. As a result, it seized and bent the end of the Steam Pipe during the pull. I am now not sure how the Steam Pipe is fixed in this bush, as it does not have threads at the end, and there seems to be a halite washer at the bottom of the groove in the boss. The joint was pulled up tight onto this washer, and not on to the main flanges as expected. I need to understand this joint before pressure-testing the boiler. Also, to make a plug where the turret has been removed.

Because of the seizure, the superheater header was damaged by torsion on removal and will require replacement. The whole superheater was copper as per LBSC. The central two flues were almost completely blocked at the front end – and can have been contributing little on a good day. The positioning of the headers differed from LBSC's drawing. They avoided a 90° sweep bend in each superheater (good) but being very close, and overlapping viewed from the front, prevented any access to or inspection of the flue ends without removal of the boiler. I would prefer to have the bends next time. One of the outside elements had had a slight leak towards the firebox end, and was covered with limescale at this point. Also, the pipe for the snifter was very weak and broke off completely during removal – it could easily have had a hole, and was, in any case, far too small. The drawing operation required a considerable pull on the Weston Block. It needed a post to hold the boiler on the ground, and Emma Rose to prevent it tilting sideways under the pull. As the spear-ends approached the front tube-plate, the soot made them go stiff again and I had to give a second pull with the block to remove the elements. If I'd realised why it went stiff again I might have been more gentle. The flues may now be strained at the front (though they still seem circular on inspection) and the ends of the spear-points came out bright copper where they had ground through the muck. A pressure test of the boiler is now essential.

22 April 2001

Made up a fitting to compress the packing where the steam-pipe enters the superheater header in case the pressure test blew the steam pipe from the boiler. This differs from the LBSC drawing, in that the bush seems permanently soldered to the boiler, and there is what looks like a Hallite washer in a deep recess serving as packing around the steam pipe sealing it. The steam pipe has no visible threads at the superheater end. Mark said that an O-ring in this position is the preferred sealing method nowadays. During the boiler test, there was massive leakage here – a 1/8" dia jet, not a spray – either through the regulator – which Mark again said was very common, and which I had noticed during previous tests – or around the now deformed steam-pipe not at all improved or sealed by tightening the dummy fitting a bit, which I did try.

The boiler test to 150 p.s.i. (but only held for a few seconds) showed no leakage at the front tubeplate around the superheater flues, so I don't think I did do any damage to them.

There was slight leakage from the regulator dome, so I removed it. The regulator is a disk regulator, with circular holes – which is why it was so insensitive. Having removed the dome, I see I can remove the disk easily without dismantling the pipework and remake it, or remodel one of the ports so it's pear-shaped.

I then thought I could test the chassis on air. There was lots of air blowing straight up the chimney at all times – not discrete puffs. The loco was very lumpy in the way it went round. Peter L suggested I might check if the packing in the cylinders was OK before concerning myself with the valves. I removed the steam-chest cover. There is an inspection port drilled in the cover so could haved checked for port-face wear without disturbing steam pipes – having once removed the smokebox. The valves were perfectly free in the buckles, and the buckles were OK on their shafts. The face of the steam-chest was quite badly scored. Len suggested that the valve faces would be scored to match, and that if I left them well alone they would probably be OK. If, however, I took them off, they would not go back properly and I would have to flat the whole lot off.

To look at the packings, I shall have to drop out the cylinders ! Just trying to move the valves back and forth by hand revealed a huge amount of "backlash" in the motion – perhaps 1/8" or more, and coming from almost every joint in the system.

Particularly bad are

Little Ends

Big Ends

Die-blocks in slides, and pins into die-blocks

Anchor links, and remaining joy linkage

Central axlebox was loose fore/aft in horns.

Club Minx seems to have split axleboxes – could facilitate repair.

24 April 2001

Last night spoke to Paul Gammon about superheaters. He suggested rather than having two headers, it would probably be possible to solder the wet side direct into the boss, and only have a dry header. This would facilitate entry of the fluebrush – not possible with the twin header arrangement I had before. Measured existing boiler and set out a suitable layout by CAD (took till 2am) and faxed it to Paul today.

This evening measured the slop in the valve-gear. The valves can move 3/32" back and forth because of slop. Decided to begin at the beginning and attend to the reversing lever. Bushing did not seem to be appropriate. Instead, I re-made the two stepped bolts on the reversing lever. When doing this again, the plain sections of these bolts could be adjusted to closely match the thickness of the lever and any washers, rather than choosing an arbitrary exact fractional length.

Looked carefully at the scoring on the valve port-face. This could be the source of my troubles. The cylinder block is not a casting, so may perhaps be unsuitably soft? Whilst Len had said the valves were probably OK if not disturbed (matching grooves) the buckles could twist slightly, and if they did, would move the valves sideways enough to jump the grooves. This could have been happening under running conditions, and has certainly happened now. The glands don't give very good support to the valve-rods, either – the joint at the end of the rod can move up and

MDSME Minx Valve Ports - scored

MDSME Minx Valve Ports - scored

down quite considerably, and so can the buckle inside the valve-chest. This scoring is so bad I can scarcely believe it could be due to char coming down the chimney. It looks far more like very severe pick-up between similar metals under heavy pressure without adequate lubrication. I note that the lubricator just pumps oil on to the port face centrally at the front. This does not seem a very certain way of applying lubrication where it's required.

02 February 2002 - 50 today!

Since Christmas I have got to grips with the superheater elements, made my bush and silver-soldered the whole shebang together. Used Johnson Mathey Stainless-steel grade flux (like easiflow, but stronger) worked a treat. Jones Industrial Fasteners, Surbiton, provided long stainless M4 socket cap screws from stock. Bought 10. The bottom centre hole in the brass header broke through into the hole for the element. I had hoped the element would go in far enough to seal it, but was not careful enough setting up for the soldering, so there was a blow.

So drilled the hole out well clear and made a brass tube to fit to finish with 0.025" wall thickness. Reheated all, and it soldered in OK. For all these soldering ops I had about 0.002" clearance between element and boss. I additionally filed 4 nicks with a three-square file along the length of the hole to encourage the flux and solder to flow properly. To bend the steam-pipe, I filled it with Woods Metal and bent it round something about right. Len says Woods Metal deteriorates under direct heat, and it's better to melt it in boiling water, and scoop the tube full under the water. I tried having the pipe hot standing in a bottle, and poured metal from the ladle into it. Didn't work well – the filling had voids, and my first bend collapsed as a result. So I heated the tube with a blow-torch to re-melt the metal. 2nd time was lucky.

Re-made the steam-pipe union nut as the old one had almost no thread in it. Decided to connect snifter to centre of brass bush, and should have made bush with not a big through centre-hole, but with a tiny hole countersunk to accept a nipple. Maybe next time.

Thought about re-running lubrication to enter the main steam-pipe. This could enter the short brass stand-pipe just above the valve-chest cover. It would be below the bottom of the smokebox, and the pipe could run across the top of the valve-rod glands, tuck in through the smallest of nicks in the bottom of the smokebox assembly, then enter the steam pipe. May or may not do this.

Dropped cylinders out of frames last week to check out packing.

Valve port-face is worn down about 0.007" where valves run, and scored heavily as well. Think this is "similar metals" picking up. Could silver solder new portface?

MDSME Minx: Piston Assy 1

MDSME Minx: Piston Assy 1

Valves are milled very shallow – say 1/8" – and have been milled with a standard endmill (approx 1/8" dia) so there is no rounding of the bottom(top?) edge at all!

One cylinder had almost no packing left – was present about 1/3rd of way round only! I was surprised by the huge groove for packing – looks like it's for standard ¼" square packing! (slightly under ¼ x slightly deeper than ¼). Cylinder bores are also slightly scored – see spreadsheet of measurements of wear.

06 February 2002

"Borrowed" some old multi-strand packing yarn from the club workshop – about 5/16" dia. It just forced down neatly into the piston grooves as if made to measure. I trimmed the ends with side-cutters a strand at a time till they butted up neatly against each other making a straight joint. Decided to do nothing to the bores or to the valve port-faces this time round.

Paul H. suggested perhaps taking 1/8" off the whole portface, and putting a sheet of gauge-plate right across the whole port-face held down by the studs, and only needing new ports cutting in it. That would give dissimilar metals for valve and portface.

The crosshead I attached with araldite years ago is still firm. The other one is now loose, and I intend giving it the same treatment. Just now I also want to wash the frames clean before any re-assembly.

MDSME Minx Crosshead Assy closeup

MDSME Minx Crosshead Assy closeup

08 February 2002

Yestderday I Araldited the other crosshead, and washed the frames in paraffin in the garden. They were astonishingly vile, and now everything's gritty.

Today found some 3/32 copper pipe hanging on the back of the door suitable for the cylinder drains – to do tomorrow. Today it's been the pump. Removed the plunger. It has an "O" ring ref 010 3/8" OD and 1/16" thick for ¼" ID. This hasn't been changed since I started running the Minx, and has flats on the outside. There was a lot of slop in the eccentric strap which I measured. Milled 0.020" off the mating faces of the rear strap to close up the slop. It now is barely tight – just needs a little running in. Then turned my attention to the bush in the eccentric rod. Re-made this in phosphor bronze as press-fit in ¼" bore with 5/32 hole. Also re-made pin which I gave 5BA nuts. I think they may have been 4BA before – but it makes no odds. The final reaming of the bush after fitting would have been better carried out in the drill, or otherwise controlled so the reamer went through properly at right angles. As it was, I had to incline the reamer in the hole afterwards to straighten it all out – not the best possible thing.

10 February 2002

Yesterday replaced two of the cylinder drainpipes while I had the block out of the loco. One was easy, one was a pain, filling with solder. Loctited (601) the draincock actuating levers on the squares on the same valves – they came off because I was a little ham-fisted removing the linkage. This evening, cleaned all the bolt holes and studs prior to re-assembly. Halford's blue instant gasket is good to 150°C – will probably be OK on steam chest – anyway I used it for the rear cylinder covers.

15 February 2002

Having waited most of the week for some Green Hermetite Steam Gasket compound good to 300°C I decided not to use it as I hadn't realised it sets hard to make a permanent joint! The facts are as follows:

Saturated Steam at 100psi has a temperature of 165°C

Superheat of 600°F = 315°C

Superheat of 700°F = 371°C

(Paul H says that steam chest pressure is only about 40psi at the best of times anyway!) Anyway, the previous sealing compound was some sort of flexible rubber, and rolled away very easily, so have re-assembled it with the Halford's instant gasket instead. Replaced two loose studs in valve-chest cover using loctite. Temporarily bolted down valve-chest cover to compress the instant gasket. Cut a new gasket from 1/64" jointing material to go immediately under the cover. Marked the holes through with my new transfer punches, and cut them with my star-head leather-punch.

Re-attached drain-cock actuating linkage. Bolted cylinder block in place again with loctite, and new washers as some were missing.

I notice the loctite (240 threadlock, now several years old) is very fluid and has changed colour from the thick blue it

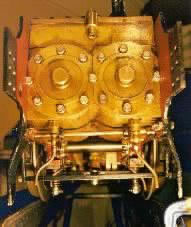

MDSME Minx Cylinders Front

MDSME Minx Cylinders Front

was to runny and green. Maybe I need to check it's still working tomorrow by unscrewing a bolt? Replaced the "O" ring on the pump.

Last night I removed the front buffer beam to get at the setting holes in the front cylinder covers, and this evening am struck by how handsome a job the front of the cylinders are. The covers have a very pleasing annular ring on them, and the hex plugs centrally are again perfectly done and elegantly chamfered. The bores and front covers are stamped 4 and 5 in bottom outer corners.

26 February 2002

The other day I milled connecting rods to length based on measurement from wristpin to crankpin – gauged with pair callipers and a telescopic bore gauge used together, and using 24" vernier calliper to measure the result. More recently, have been machining the big-end brasses from a lump of bronze. The material seems quite soft and machines easily, but without the chatter & needles of brass. Instead you seem to get granular fragments from the drill. Soft-soldered the halves together. Used the lathe to bring them to thickness. Used the horizontal mill to do the edges and machine the ¼" grooves. Messed up on the 3rd groove because I thought I had to put some more cut on as well as turning the brass over! Wrong! Can fix by loctiting a couple of bits of shim in the groove to bring it back.

MDSME Minx Crank Axle 2

MDSME Minx Crank Axle 2

Measured the crank journals in the middle – one was 0.714" and the other 0.713" in all attitudes of the crank. Unfortunately, I didn't measure them at the edges. Having bored the brasses (clamped to the faceplate so as not to distort them) to as I thought 0.001" clearance – and isn't it wonderful to be able to measure the i.d. reliably and repeatably with the telescopic bore gauge - the first pair gripped like brake shoes! I re-measured the journals, and although they are round, they are thinner centrally than at the edges. Where the journal joins the web they are 0.718" or 0.720". (The worn brasses I am discarding have a major diameter of 0.735"!) At first I considered re-mounting the brasses in the lathe and taking some more off, but instead, decided to try scraping. I blued the journal and began, scraping off metal where the bore showed the blue. It took an hour or so, but I am well pleased with the result with the first pair. Reboring would not have achieved a fit in the same way – and would have had its own re-setting and dimensional difficulties.

Lastly may I wish you all a very Happy Christmas and a Happy new Year .. Mark, Sue Tom & Lizzy ...... .. . . .. . . . . . . .

2002/3 Events Calendar

Thursday 26th December Boxing Day Steam up.. 10am onwards

Saturday 28th January SETUP The Model Engineer Exhibition, Sandown Park Exhibition Centre,

Esher Surrey, See Peter Larkin for details

Sunday - Tuesday 29th Dec - 31st December The Model Engineer Exhibition, Sandown Park Exhibition Centre,

Esher Surrey, See Peter Larkin for details

Friday - Sunday

24th - 26th January London Model Engineering Exhibition;Wembley Exhibition center, Wembley West London

(£8.00 adult, £5.0 children, Concessions £7.00, family £21.00 }

Friday - Sunday

14th - 16th February Model world 2003, Brighton Centre, Sussex

Sunday 13th April Tune up Sunday, BOILER TESTING.

Friday 18th April Good Friday, final clear up.

Sunday 20th April Easter Monday, 1st Public open day for Year 2003, BBQ 6.30

Monday 21st April Easter Monday, Public open day.

Sunday 4th May Public Open Day, BBQ 6.30

Monday 5th May Public Open Day. Spring Bank Holiday

Sunday 25th May Public Open Day, BBQ 6.30

Monday 26th May Public Open Day, Late spring Bank Holiday

Working parties every Sunday 10am onwards at our headquaters and track.,

Bring your own lunch. Free tea / coffee /juice, all ages and skills catered for, just turn up.

'Saga builders' working parties Tuesdays 11:00 through to 16:00, all year round,

contact Peter Pullen, Bring your own lunch. Free tea / coffee

Worshop group, working party team every Wednesday 20:00 all year round,

contact William Goffe

Details of any further events will either be on the club notice board or via membership mailing.