The Roundhouse Journal August 2001

Editorial

Discovering a Wall a doubly exhausting track day

On the 28th March, I received an email from Wall to Wall Television asking about the club. Their researcher was identifying railways to be filmed for "Off the Rails", a 20 part series for the Discovery Channel. They had encountered our web site and this had awakened their interest. The series is to consist of 18 episodes on standard gauge railways, one on narrow gauge, Leighton Buzzard, and one miniature railway – and for the last they chose us.

Thence followed a somewhat hectic period during which the feasibility was reviewed, the committee agreement sought, a date identified and an action plan put together. In late April, the film director made a research visit to Thames Ditton to see if there would be sufficient interest generated in an episode on a miniature railway (one had not been part of their original plan), and to identify what might be filmed. Well, things looked good and intentions confirmed. The first track day in May, Sunday 6th was chosen and a timetable was put together. A key part of the approach was that the presenter would participate in all the activities to be filmed, and as this was to include driving, we had to ensure those activities would be conducted when the public running were not around.

So, sharp at 0830 on the 6th as promised, the film crew arrived. Many club members were already there and I had arrived by the skin of my teeth only just before the film crew. After introductions, some food (always a good idea) and plenty more discussion, we got under way. The film crew split up into two teams, one with the cameraman/director and presenter; the second cameraman and a sound assistant comprised the second crew, supported by someone on work experience. First problem – they had not brought all the bits they needed for the second crew, so off went one of the them for a 3-hour return trip to collect the missing bits. The main team carried on regardless.

The first scenes to be shot featured the opening up of the site at the start of a typical day. Sean Hampshire had been press ganged into being the star for this stage. It involved chatting to the presenter whilst unlocking the compressor shed and getting the presenter to switch on the compressor. Sean gave a detailed explanation of what it the air was used for: points, steaming up, etc. They then went around to the carriage sheds and hauled out Goliath (Goliath is a ground level track oversized toolbox weighing about 1 tonne).

Goliath was then pushed around to the maintenance shed. It had been arranged that I would screwing on the penultimate sleeper onto a length of track just as the presenter walked up. Some chitchat was filmed and then the presenter was invited to fix the last sleeper on. This reminded us that while we get used to attaching the sleepers with the power tools, when you do it for the first time it is not quite so easy as it looks – the sleeper just would spin round rather than the screw doing up, or the driver would slip off the screw head.

The newly completed length of track and one more length with a buffer stop were then lifted on top of Goliath and pushed around to Willowbank station, going through the rigmarole of opening the level crossing gates on the way. At Willowbank, very conveniently, was the readied track bed for the coal wagon siding, edge beam completed and ballast ready to the level of the base of the sleepers. The track was lifted down into place and the process of cutting to length and welding in place was started by Rupert Goffe.

At this stage, because we needed some time to complete the track laying, the film crew went off with James Mottram to put out the signals; collecting the signal truck from the roundhouse and setting off around the track to put out the signals. The director particularly liked the experiment metal grilling used on the signal gantries and took film from beneath the gantry and through the grill to the presenter above – a genuine bottom up approach was filmed as he was passed each signal. Signals were duly plugged in, checked (like we always do don't we) to ensure that is would show the danger and proceed aspects.

By the time the signal truck got around to Willowbank we were ready with the coal siding track to film the welding up of the last joint. Then we invited the presenter to shift in some ballast (which had conveniently arrived in two barrows on another truck) and to finish off the track.

A quick time check stunned us – we were still running to time – it couldn't last could it – well it didn't.

The next step was for the presenter, having worked so hard for the morning, now to get his bounty – a drive on the raised track. Continuing the miracle of the planning so far, Ken Parker was ready to move off the steaming bays with his Firefly (the locomotive to be filmed) and Steve Gray was ready with his Maid of Kent – to be used to pull the film crew on the adjacent line. First some tuition and donning of safety spectacles – the film crew were very keen to be filmed using all the safety gear and where relevant following appropriate safety codes – such as the use of high visibility vests. Apparently they are invariably scrutinised by either the production company or by the viewers to ensure that things are just right or better safety wise.

Here came our first problem. The film crew complained of electrical interference messing up the sound track when trying to interview Ken. Ken was trying to explain the workings of the locomotive and a bit about its history. He was close to the locomotive and it was gently blowing off. No cause of the interference could be found – and the crew were convinced that the only possible explanation was that there must really be some electrical thing a majig on the locomotive. No sorry folks – that's not the answer. Finally it was rumbled. A quirk of the sound system was that through the earphones you could not hear the safety valves blowing – they must just have been generating noise at the wrong frequency for the sound system. So all that was left to hear was the frenetic sound of tiny bubbles forming in the boiler – which just one cannot normally hear with full spectrum bionic sound system (ears) because they are drowned out by the sound of the escaping steam. Put on the injectors – yep that stopped the electrical interference.

The crew really had a good time going round and round the raised track – retake after retake – but both locomotives performed impeccably and gave and excellent show. However time had drifted on way beyond what had been allowed – public running was approaching far quicker than it ought. There was absolutely no way that we could allow the presenter to drive when the public were present, either from the safety or from the disruptive point of view. Having said our goodbyes to the Raised Track and crew, lunch was deferred and we rushed straight to the ground level Roundhouse.

Mike O'Brien was ready – as he had been for some time – with Samantha. We skipped the planned shooting of the locomotive being readied and coming off shed, and went straight to the presenter driving the locomotive in the carriage sheds and collecting the coal truck. It was arranged that presenter would drive the locomotive with the coal truck around to Willowbank, with the cameraman sat in the coal truck filming over the presenter's shoulder. Mike O'Brien was to walk alongside and slightly behind as conductor.

With the presenter having become accustomed to rattling around the raised track at a decent rate of knots, it soon came to pass that Samatha's speed increased and Mike got left behind. By the time the train reached Willowbank box it was going at a fair line speed. Only problem was that the cross over from the main into the central platform loop was set and the next cross over taking one into the forward headshunt siding was also set – as planned. But not surprisingly our visitors had not learnt the signals. So despite the camera running there ensued a fair bit of shouting – mainly the word "stop" comes to mind.

They rode the crossover into the loop impressively and eventually brought the train to a halt – but over half the distance to the impending buffers had been traversed. Hmmpf. Never mind, back up please far enough that you can be filmed slowing down and please take it steady into the siding. The whole purpose of this was now to show the coal truck being shunted onto the siding that we had installed earlier. So into reverse and set back from the headshunt into the coal siding carefully – please don't run the truck hard into the buffers. Well – the second film crew and a few members did laugh a bit as driver and cameraman found out just how quickly a miniature train will stop when it hits an unsprung buffer stop.

Now, out of the way please – the public are here. Just a few minutes before running time we cleared the crew away into the clubhouse to enjoy sandwiches and more courtesy of the kitchen. While munching, Rod Janes had provided a comprehensive set of photographs of the track, site construction and the tunnel which were carefully perused and commented on.

After lunch the two film crews went their separate ways. James Mottram having the delight of keeping one crew safe while taking pictures of trains running at various locations around the site – while the main crew set to complete filming the scenes of Samatha that had been skipped earlier. So now Samantha was apparently readied at the RoundHouse, Mike O'Brien was interviewed and then the locomotive was driven around to the carriage sheds – so the film could be sorted out later into a sequence that actually made sense.

Also in the afternoon, we disappeared into the workshop where Jerry Birchell was ready with his chassis Ivatt Class 2 Tank that is under construction. Jerry's loco had been chosen because it was at the well completed chassis stage – providing the opportunity for some close up filming – and there is a lot of fine detail in that chassis that is well worth a look. Quite a lot of narrative was captured, and some very detailed close-up shots taken to show the public just how much effort goes into these models. Then, oh dear, sorry Jerry – the batteries on your microphone seem to have run out – better check when this happened – actually just as you started talking – could we do all that again. Well it is a good job that Jerry has built up patience building his locomotive – no ruffled feathers or anything – not quite word perfect to last time but a pretty good like for like second run.

It was now getting later in the afternoon and the director wanted to film the presenter's opening speech. Do you always do the opening speeches last? Apparently so. We enlisted Tim Reynold's London Transport Tank as the centrepiece for this and marshalled it in the loop (as used for Santa specials) at Hampton Court Junction. The sun – which had mostly been patchy, bright but not too stunning during the day final decided to get serious. This meant that the late afternoon shadows were very strong. As the locomotive was facing the normal direction of running it mean that the light was all wrong – so the loco had to be turned around and everything tried facing the other way. This then went fine, except well there were quite a lot of people about – and none of them realised that with long shadows – even walking a long way from the shooting still cast shadows over it.

By now the public had stopped running and it was now time to take Tim's engine back to the roundhouse. I went off to the signal cabin to change the road. As I crunched across the ballast I found dogging my heals a smiling presenter chuffing along quite happily in reverse with the loco. "No, you can't just follow me – you have to wait until the points are set the right way and then are then asked to move off – please can you go back to where you were so we can set the right road?" "OK." Now moving forward, which was much easier as you do not have to twist around, the presenter seemed much happier … but then did not stop where he had been but went off out the other end of the loop for a trip around the track the running the wrong way!

Lots more noise from people, and the presenter stopped looking straight into the face of the Hymek going the other way – I am not sure if it was the presenter or Tim that ended up looking most worried. What fun we can have.

The final act of the day was for the film crew to join in with the barbeque. Again we were fed from the Stellean infinite food chest (has anyone ever seen it run out?). The film crew then were inspired with a joke that even I would have trouble with (ask my wife about my jokes). They asked that I prepare a 1/8th size steak and grill it – so that we could feed the presenter with an appropriate scale meal – at least it was not fish as that would have been a meal with scales. This was duly served on film, with the presenter pretending to put on a sad face and then threatening to go for a broad gauge railway next time for better nosh.

Finally, some 12 hours after arrival, the film crew left, things were put away and we all went home. I had learnt that looking after a film crew is much more exhausting that normal track day work. Inevitably during the day some of the planned activities were skipped as we had more material to film than time permitted. So sorry to those who prepared themselves for demonstrations or interviews and then finally did not get called forward. It was better that we had too much to film than not enough. Thanks to every one who helped, who made the day a success and who kept the impact to the public as small as possible. Certainly the film crew enjoyed their day at the club and the hospitality. Afterwards they sent the following message "Hi Martin - it's Steph from Wall-to-Wall here. Thanks once again for a lovely day at your railway".

About 10 hours of film were taken in total by the two crews, giving a ratio of 20 minutes filming for each minute to be shown.

So a lot of what was filmed that will only serve to lie in secret in the film archives. What will be shown the final episode remains to be seen. The broadcast is expected to be later this summer or the autumn. We hope to let you know the date of showing. For those who do not access to the live transmission, we have been promised a copy of the film so we can show it in the clubhouse.

Martin Baker

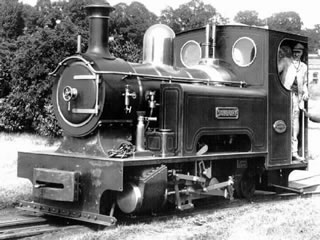

"HAMPTON" – A Kerr Stuart 0-4-2 ST

Many members will no doubt be aware that I am building a model of another Kerr Stuart narrow gauge loco in 7¼" gauge to join my existing Kerr Stuart "Wren" class loco "Rosemary" completed in 1986.

I was first shown a picture of "Hampton" by my grandfather when I was 10. I was immediately struck by its very smart appearance. Another point that attracted me to it was the fact that the loco used to operate on a railway only half a mile from my (then) home in Hampton!

In 1989, I managed to obtain some prints of some of the original Kerr Stuart drawings from Hunslets in Leeds, so I duly decided to start the model.

Before going on to describe the model, I will start with describing a little of the history of the prototype and the railway it used to run on. A 2ft. gauge railway was built by the Metropolitan Water Board in 1914-15 to link the waterworks at Hampton, in Middlesex, with those at Kempton Park and Sunbury. There was about 3½ miles of track laid in 35lb/yd rail. For a quarter of a mile the gradient was 1 in 20 with a further half a mile at 1 in 40! The sharpest curves worked by loco were 40ft radius.

The railway started at the Water Board's wharf on the River Thames. Here barges of coal were offloaded by crane into coalbunkers, which were then emptied into tipper wagons. The line then climbed away from the river towards the Sunbury and Kempton Park works. At Kempton Park there was a facility for transferring coal from wagons on a standard gauge siding from the L.S.W.R. Shepperton branch into the narrow gauge tipper wagons.

The various boilerhouses were served by a network of branches and sidings off of the main line. To provide motive power for this new line, a design and specification for the locos were drawn up by the MWB chief engineer Sir James Restler and his loco superintendent George Tyas. George Tyas had worked at Kitson and Company in Leeds so was well placed to prepare such a specification. The drawing specified an 0-4-2 well tank 15' 3" long, 6' wide maximum and 8' 3" high. It also specified cylinders 8½" x 12" stroke with Joy valve gear.

The contract to supply the three locos was won by the Kerr, Stuart and Company. From the specification they came up with a design that was as follows:-

Length over buffers - 15' 3"

Length over buffers - 15' 3"

Width - 6'

Height - 8' 3

Weight (in working order) -

10 tons 15 cwt

Driving wheel diameter - 2'

Fixed Wheelbase - 36"

Cylinders - 8½" bore x 12" stroke

Outside Walschaerts Valve Gear

Side Tanks of 170 gallon capacity

4 sandboxes

Sliding Firehole door

Livery was green, fully lined. The dome and safety valve covers were polished brass. As can be seen from figure 1, they were very attractive locos. The locos built were named "Hampton", "Sunbury" and "Kempton" (KS works numbers 2366, 2367 & 2368)

Unfortunately the railway was dismantled during the Second World War. A few traces of the original formation remain, including an overbridge. As for the locos, as far as I know, the only items remaining are a loco handlamp and a loco head light, which are on display in the Kew Bridge Pumping Engine Museum.

Anyway, enough of the history, I will continue with some details about the model. I am building the model to exact scale as far as possible. This gives a scale factor of 7.25/24 i.e. 0.3021. This is between a third and a quarter scale. The overall dimensions of the model therefore work out as 55¼" long (over the buffers), 21¾" wide and 30" high. The driving wheels are 7¼" diameter and the cylinders are 2 ½" bore x 3 5/8" stroke.

For drawings for the model, I have worked in one of two ways. For the simpler items I have just photocopied part of the appropriate sheet of the full size drawing and then written the scale dimensions on. For more complex items or assemblies I have drawn the necessary drawings in AutoCAD.

In order to avoid the need to have to make patterns and get castings made, I have fabricated components or machined them from the solid. The driving wheels, which only have three spokes, are machined from steel discs. The cylinders are machined from blocks of cast iron bar and the smokebox saddle was fabricated from plate and tube.

As on the prototype, the model is fitted with an axle driven water pump.

Although I made the boiler for the "Wren", I have cheated this time as I have had one made for me by John Ellis. It is basically to the Milner Hunslet design, with differences to the external dimensions to suit my loco.

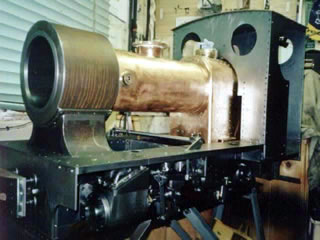

The pictures (figures 2 & 3) show the progress to date. The chassis has been tested on compressed air, although it is not quite finished. For example, I haven't made the springs yet as I am waiting until I have the weight of the loco before designing the leaf springs!

The pictures (figures 2 & 3) show the progress to date. The chassis has been tested on compressed air, although it is not quite finished. For example, I haven't made the springs yet as I am waiting until I have the weight of the loco before designing the leaf springs!

At present, I am working on the cab and coal bunker. The complete cab back will be removable to make it possible to drive and fir the loco. As can be seen from the photos, there was a sliding hatch in the back of the cab. Initially I assumed that this hatch was to assist in raking out the fire. Now I am convinced that it was to enable the driver to couple and uncouple the wagons without leaving the cab. The next job will be to make the side tanks. One job I am not looking forward to, is making the dome cover! The polished brass dome cover was such a prominent feature of the prototype and it has to be right!

I keep being asked how much longer it will be before it's finished. So far, I have spent just over 1500 hours on construction (plus a couple of hundred on drawings etc.). I would guess that there are at least another 500 hours to go. So perhaps in 4 years time (2005) it might be finished. Construction has stopped as I write this because I have had an operation on my right hand, which means that I can't use it!

I keep being asked how much longer it will be before it's finished. So far, I have spent just over 1500 hours on construction (plus a couple of hundred on drawings etc.). I would guess that there are at least another 500 hours to go. So perhaps in 4 years time (2005) it might be finished. Construction has stopped as I write this because I have had an operation on my right hand, which means that I can't use it!

Alain Foote – May 2001

New Tyres for Old from The Old Buffer

Poor little Sweet Pea! The new steaming season was about to commence and Matilda was due for her boiler certificate renewal. She was duly taken along to the clubsite on boiler testing day and put through her paces. She passed her hydraulic and steaming tests but the boiler testing gentlemen were not at all satisfied with the state of the steam fittings. The steam valves were not shutting off completely, the clacks were weeping and the blowdown valve was not sealing off.

There was nothing for it but to take her home and embark on a major overhaul and, where necessary, replacement of steam fittings. The more dedicated among us would have set to on their lathes and manufactured the replacement items, but I decided that I would part with some carefully hoarded pennies and go for "off the shelf " items. Even so, adopting this course of action was not so simple and straightforward as it might have been, but after a bit of head scratching, most of the problems have been resolved.

While the Sweet Pea was in a semi-stripped down state another problem revealed itself. It was observed that considerable wear had taken place on the rear wheels. The tyres had worn to the extent that the wheels could have been used to roll miniature channel. This prompted the question of what reconditioning procedure could be effectively applied. The first thought was to obtain a new set of wheel castings, machine and fit them. As the front wheels appeared relatively unworn, it was decided to refurbish only the rear wheels. In the light of this, if new wheels were machined and fitted to the rear axle, they would require quartering. There are various ways of performing this task, but who is to say that the end product would match the quartering on the front axle. This was assuming that both axles were quartered at the same time and on the same jig or whatever. The decision was reached to turn down the outer diameter of the worn wheels and fit new tyres made from steel, hoping that they would wear better than the cast iron wheels. At the same time the existing relationship for the quartering would be retained.

The next requirement was to source the material from which to make the new steel tyres. It just so happened that I passed by the scrap bin at work one day and checking the contents as is my wont, I espied the fag end of a piece of tube that had been discarded. A quick measurement confirmed that this could be the just the job. Priority wombling procedure was brought in to play and the piece of scrap tube was quickly squirrelled away to a place of safety in readiness for me to attempt to transform it into the new tyre and flange profiles. There would be a considerable amount of metal to remove but as the rule book states, Womblers have to be satisfied with whatever has been thrown away.

Not having the facilities at home for this exercise, permission was sought and obtained to turn the new profiles on the lathe at my place of work. With limited time available, the excess material had to be removed at a rapid rate. This meant giving the lathe some welly, swarf coming off blued despite flooding with coolant, and picking up a couple of minor burns when some of these hot chips hit the back of my hand. H and S fanatics please note that chuck guards were in position during this exercise, but some errant swarf chip always seems to find its way around these defences. This is one instance where one is grateful for replaceable tungsten carbide insert tooling enabling one to carve off large quantities of metal at one bite. Finally after much huffing and puffing, involving delineating the illegitimacy of certain pieces of metal and related components, the new profiles were produced.

Meanwhile the Sweet Pea was residing in my brother's workshop being minus most of its steam fittings in order that they might be refurbished or replaced as required. With the new tyres now in evidence, it was decided to bite the bullet. The connecting rods, coupling rods and valve linkage were disconnected and the rear axle and wheel assembly dropped. The plan was to turn the wheels between centres while remaining mounted on the axle.

Problem. Because the crank pins were still in situ in the wheels, the standard centre was too short. In other words the crank pin collided with the faceplate before the axle could locate on the centre. Solution. Manufacture longer centre. Question. Did one want to attempt turning a 2MT taper? Answer. No. What next? Switch brain cell into think mode while at the same time rummaging through odds and ends box. This is the box in everyone's workshop which is clearly labelled MCIHL, which everyone knows stands for, Might Come In Handy Later. This exercise yielded an old stub of 7/16" dia drill about ½" long on a 2MT taper. This was used to drill a hole in a suitable length of steel rod. The drill was Loctited into the hole, which it had just drilled. This was mounted taper end in the headstock of the lathe and a centre point turned on the other end of the piece of steel rod. Since, during turning, this would be rotating at the same speed in unison with the axle, it did not matter that this would remain soft. The remaining problem was to find a lathe dog to transmit rotation to the axle assembly sitting between the centres. The dog proved elusive so the new "centre" was cross-drilled and a suitable pin inserted which rested against the crank pin. Thus rotational motion was imparted to the workpiece.

The diameter of the wheels was reduced until a light drive fit was obtained between the wheels and the tyres. Finally, the mating surfaces were coated with Loctite retainer and the tyres pressed on to the wheels. Next the front wheel tyres were skimmed in order to true them up. It had been observed that some wear had occurred which had caused the wheels to become a few thou eccentric. Having ensured that both front wheels were of the same diameter, the diameters of the rear wheels were adjusted to match. Now all the wheels should run in unison instead of fighting between the front and rear wheels because of differing diameters.

Before the wheel and axle assemblies were replaced in the mainframes, new springs were fitted all round. The rear axle was sprung on rubber blocks. I believe the theory behind this was that it minimised the amount of disruption to the valve events of the Hackworth valvegear. Prolonged exposure of these rubber blocks to lubricating oil, etc. had caused them to become somewhat gungey, and I feel sure that this had exacerbated the rate of wheel wear. Later opinion is that springs should be fitted to the rear and so this configuration has been adopted. It now remains to see whether any improvement in track running and valve operation can be observed.

As soon as various steam fittings have been upgraded along with some other minor problems that have become evident during the strip down, it is hoped that it will not be long before Matilda is back in steam, and reporting for duty on the raised track. The intention is that she will also sport a new coat of paint to help celebrate this event.

Gerald Todd.

Subscription 2001/2002

A reminder that in 99% of all cases subscriptions will become due from the 1st September 2001, Mike Evans our Hon Treasurer will be in contact in due course. Arrangement will also be made to pay subs at the club on Friday night.#

I hope you enjoy this Roundhouse issue, and may I wish you a good steaming or machining or what ever interests you for the rest of 2001.

MarkAdlington.

Events Diary 2001

Sunday 26th August Public open day. (members BBQ 6.30pm)

Monday 27t h August Bank holiday, Public open day.

Sunday 2nd September Public open day.

Saturday 22nd September Families Day (members BBQ 6.30pm) **NEW ADDITION**

Sunday 7th October Public open day.

Sunday 14th October 7¼" Gauge Open day.

Saturday 3rd November Bonfire Night + Fish & Chip + Films, TICKETED EVENT.

Sunday 25th November Present Wrap / club house prep for Santa Run ****NEW***

Friday 30th November Rummage Sale.

Sunday 9th December Santa run. - Confirmed.

Wednesday 26th December Boxing Day steam up.

Any other dates / information will be sent direct to members